EBMS includes the tools to create a bill-of-materials (BOM) used for manufacturing, materials lists, and other grouping of products. A bill of materials (BOM) is created within the components tab of an inventory item. BOMS can be nested to create a multiple level bill of materials.

The Components and Accessories tab of an inventory item facilitates the ability to associate other inventory items such as parts, assemblies, or raw materials to the item. These BOMS can be configured to create an assembly kit, materials list, parts list for a manufactured item, or accessories (optional or standard) that are sold with an item.

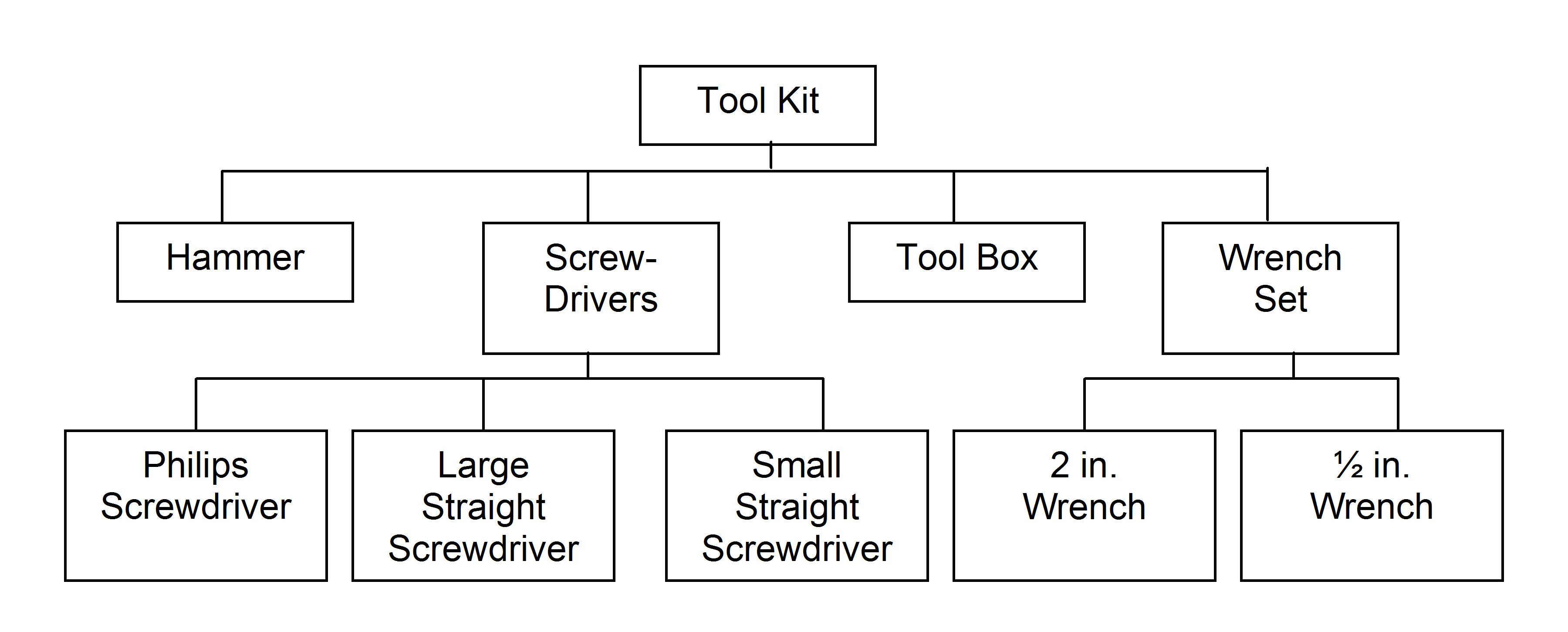

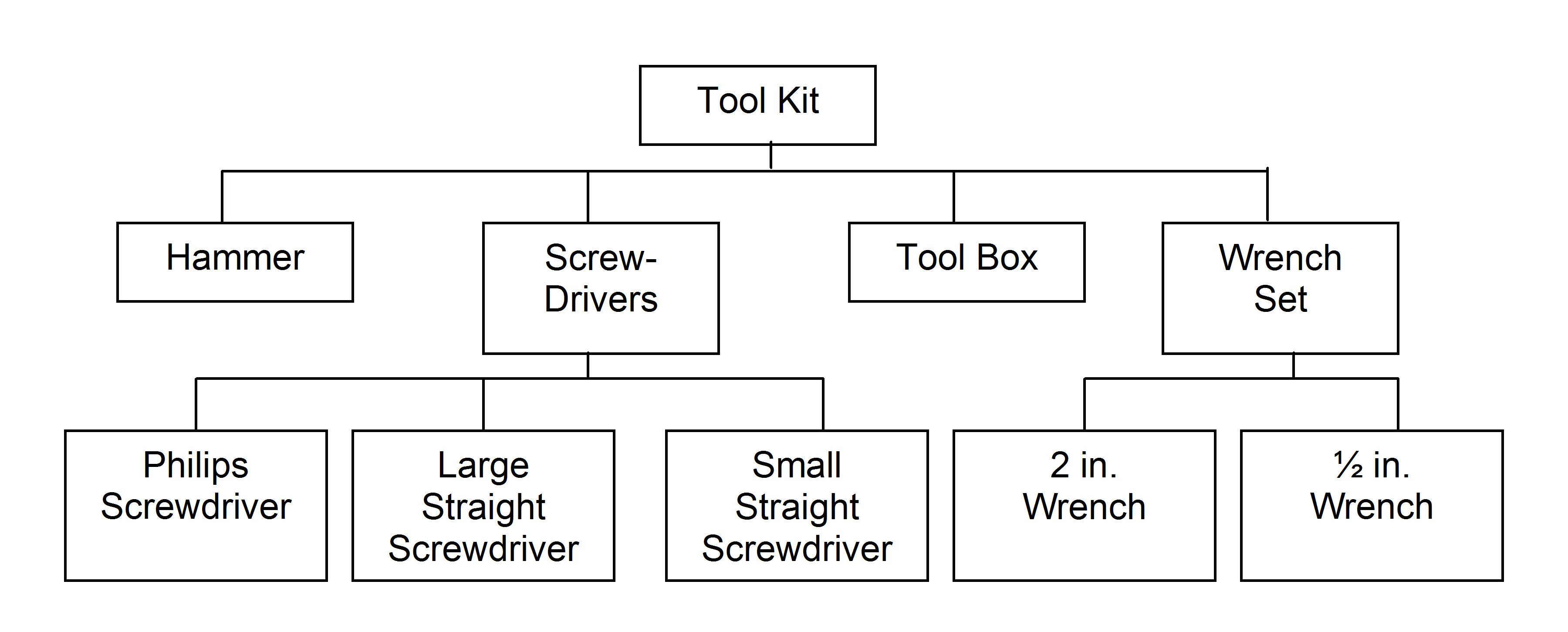

Items can be associated in using multiple levels of components. For example, a hardware store may sell a set of tools that consists of multiple inventory items as shown below:

In the example above, all the tools can be processed using one inventory item (Tool Kit). If you sold just the Wrench set, the system processes all sub-components (2 in Wrench, ½ in. Wrench) as well or if the Screwdrivers item is sold, all the different screwdriver components are processed. However, if the Hammer, ½ in. Wrench, or Philips Screwdriver items are sold, no other items will be processed since these items do not include sub-components.

The component is linked to a main item that is priced as a unit. For example, this option is used when the Tool Kit (as in our example above) is priced rather than each individual component. Inventory can only be recorded or tracked on the bottom level of the hierarchical list using this option. In the example above, inventory could be tracked on the following items since they do not have any components: Hammer, Philips Screwdriver, Large Straight Screwdriver, Small Straight Screwdriver, Toolbox, 2 in. Wrench, and ½ in. Wrench. Review the Adding Components to Create an Assembly Kit section for more details.

Components within an assembly can be optional. For example, the hammer that is a component of the tool kit may be either a small hammer, a large hammer, or another option. The system can be configured to prompt the user to choose one of the optional components when the item is entered into the sales order or quote. Review the Optional Components or Accessories section for more details creating options.

An assembly is sold for a single price but the inventory is always tracked by the individual components. In the example shown above, there are never a number of Tool Kits in stock. The other limitation of the assembly method is that when an assembly is returned, the inventory is again maintained by individual components. The assembly method works fine for the tool kit because any tool can be removed from the kit and sold separately at any time. To use the assembly method for a piece of equipment that is welded together or a small shed that is built that cannot easily be disassembled, the manufacturing process is a better option.

The manufacturing module is used when an item is assembled or manufactured from other inventory items. The manufacturing step allows the system to track counts on both the manufactured part and each component. For example, if the user prefers to track the number of tool boxes already assembled, the tool box inventory count must be increased at the time they were manufactured and the component count will be decreased. Review the Manufacturing section for more details on this process.

The Made-to-Order (MTO) option within EBMS gives the user the convenience of combining the 2 step process of manufacturing and Sales into a single step.

The Manufacturing process should be used if a batch of products are made for stock or done ahead of the sale. The MTO process is ideal when items are individually manufactured based on a sales order. This process is ideal for customer furniture, sheds, equipment, or other items that are custom built based on the options selected within the sales order. Review the Made-to-Order Kitting section for more details on this process.

The Configure-To-Order (CTO) process is used to sell custom kits with various options, sizes, styles, or configurations. This process uses the Optional Components feature to configure a custom pre-assembled item that is purchased as a unit from the vendor. Products can be purchased, manufactured, or assembled to meet the specific needs of the customer. EBMS includes powerful inventory tools to manage the orders, track inventory, adjust the pricing, and complete the financial process required to sell CTO product. Review the Configure-To-Order Kitting section for more details on this process.

The accessory option within EBMS allows the user to add accessories or options that are priced separately rather than assembled within the actual item. For example, the tool kit may contain a option that is priced separately, a printer may cause the system to prompt the user to add a cable, a custom shed may include a ramp that is priced separately, etc. These items are listed on a separate tab from the item's components. Review the Adding Accessories to an Item section for more details.

The components are linked together using a main inventory ID but each item is individually priced. In the example above, each tool would be priced individually but the entire set could be inserted into a sales invoice using a single inventory ID. The inventory counts would be processed the same way as when the user enters each individual item. Review the Adding Components to Create an Assembly Kit section for more details.

Associating multiple inventory items to a common inventory count can be accomplished using the component option within EBMS. Associating items should only be used if multiple item IDs are required for the same item. For example, two sales part numbers may identify the exact same item. Associated items should not be confused with substitute items, multiple unit-of-measure, or multiple vendor part numbers. Review the Associating Items section for more details on this option.