The Made-to-Order (MTO) option within EBMS gives the user the convenience of combining the 2 step process of manufacturing and Sales into a single step.

The Manufacturing process should be used if a batch of products are made for stock or done ahead of the sale. Review the Manufacturing > Overview of Kitting and Manufacturing section for more details on the manufacturing process. The MTO process is ideal when items are individually manufactured based on a sales order. This process is ideal for customer furniture, sheds, equipment, or other items that are custom built based on the options selected within the sales order. Complete the following steps to set up a MTO item:

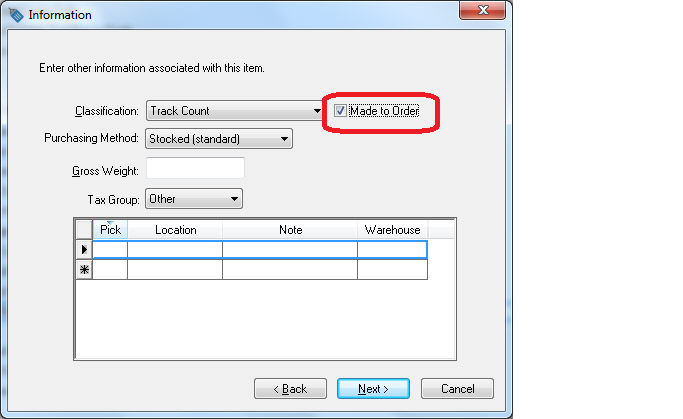

Create an inventory item using the same steps as any

other item with exception of the Made

to Order option that is located within the 2nd page of the

wizard. Note that a MTO item must be classified as Track

Count, Serialized Items, or other perpetual inventory classification.

Review the Product Catalog

> Entering New Products section for more details.

Enter the components including options within the MTO item. Review the Components and Accessories > Adding Components to Create an Assembly Kit or Components and Accessories > Optional Components or Accessories sections for more details on adding components or options.

Insert the MTO item within a sales order or proposal. Review the Inserting a MTO item into a Sales Order and Adding a MTO item within a Proposal sections for more details.

Process the sales order or manufacturing batch. Review the Processing a MTO Batch for more details.