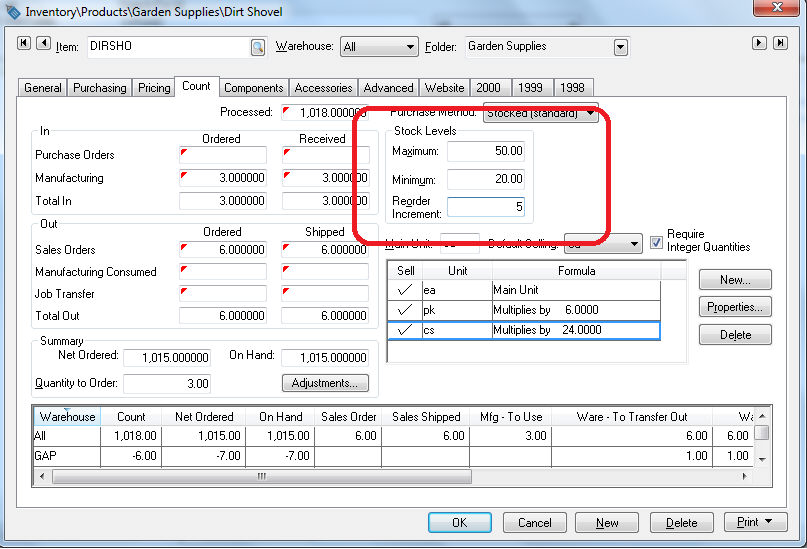

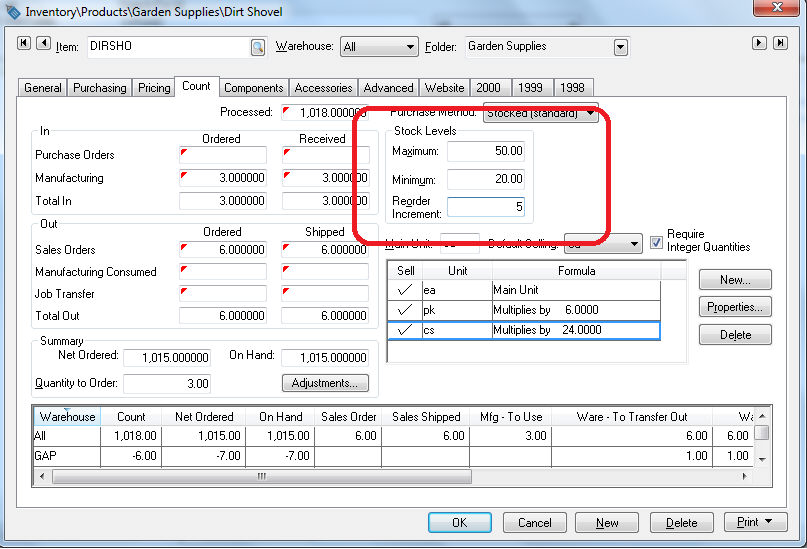

EBMS contains Stock Levels parameters that assist in maintaining proper inventory. These values are used to prompt the user when stock levels are low are required to properly use the Inventory Purchasing Page.

These settings can be found in the Count tab of the inventory item:

The Maximum and Minimum settings determine the inventory management parameters. If the Net Ordered (Count + Purchase Orders - Sales Orders) amount is less than the Minimum inventory amount, then the purchasing tool will prompt the user to purchase additional inventory. If multiple order Amounts are less than or equal to the Maximum amount, the system will purchase multiples of the Reorder Increment value.

The system will not prompt the purchaser to order inventory until the inventory is depleted if the Minimum amount is zero. The purchasing tool will always recommend an order amount set in the Reorder Increment if the Maximum setting is zero.

The minimum value can also be used to set color codes within the inventory list and the purchasing window. See the Tracking Counts > Color Coded by Stock Level section for more details.

EBMS contains automated processes to set the Stock Levels settings. Review Inventory Stock Level Settings for details on the utilities that calculate stock level settings from sales history.

An internal manufacturing vendor setting should be set as the Primary Vendor if the product is manufactured intead of purchased. Review Manufacturing > Materials Resource Planning (MRP) > Manufacturing Vendor for setup details.