Adjusting Inventory Counts as a Batch

The Adjust Counts component within EBMS allows a user to adjust the counts and values of multiple track count inventory items as a batch.

The following sequence of steps are required for each count cycle:

-

Preparing for count: This step downloads the counts from inventory which allows inventory sales and purchases to continue.

-

Creating batches: Group product in one or more batches based on location, category, manager, or other grouping of inventory counts.

-

Counting items: Physically counting items and manually entering counts or importing them using an Excel spreadsheet.

-

Count complete: All counts must be entered and confirmed before adjustments are made.

-

Review counts: Review counts to minimize the requirement to process multiple adjustments for the same count cycle.

-

Adjust counts for all batches: This step adjusts the counts within the product catalog for all batches. Note that this process is designed to allow for inventory changes between step #4 and this step.

-

Report adjustments: This optional report may be useful for give details on the financial manager, accountant, or owners.

1. Preparing for Count

At times, it is necessary to adjust inventory counts. Review the following items before creating an adjustment:

-

Review open unprocessed documents: Review all open, unprocessed documents within EBMS containing Products to confirm Shipped or Received quantities are valid and match the true state of the

open document. This may include sales orders, purchase orders,

manufacturing batches, serialized added cost batches, and job transfers.

-

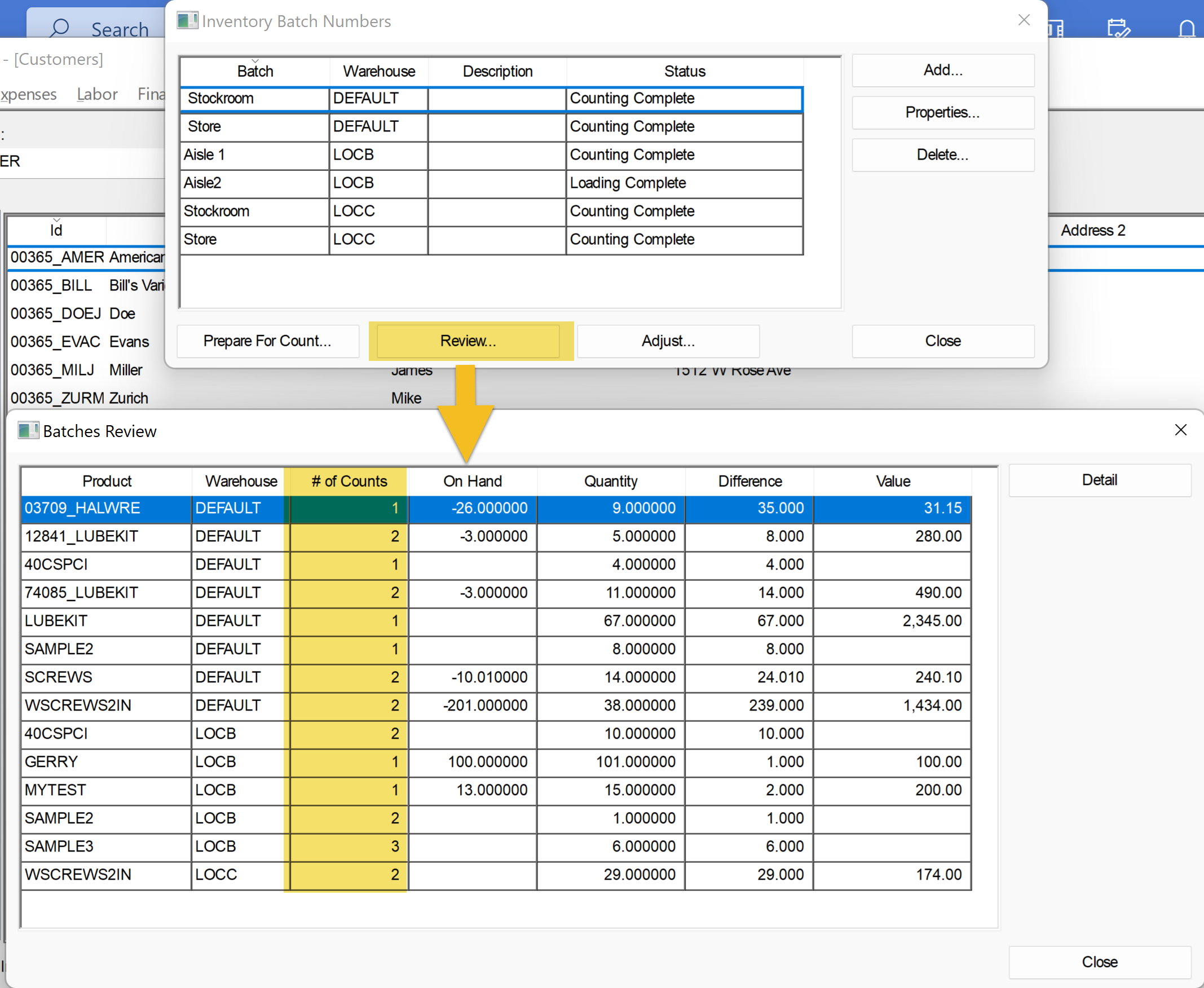

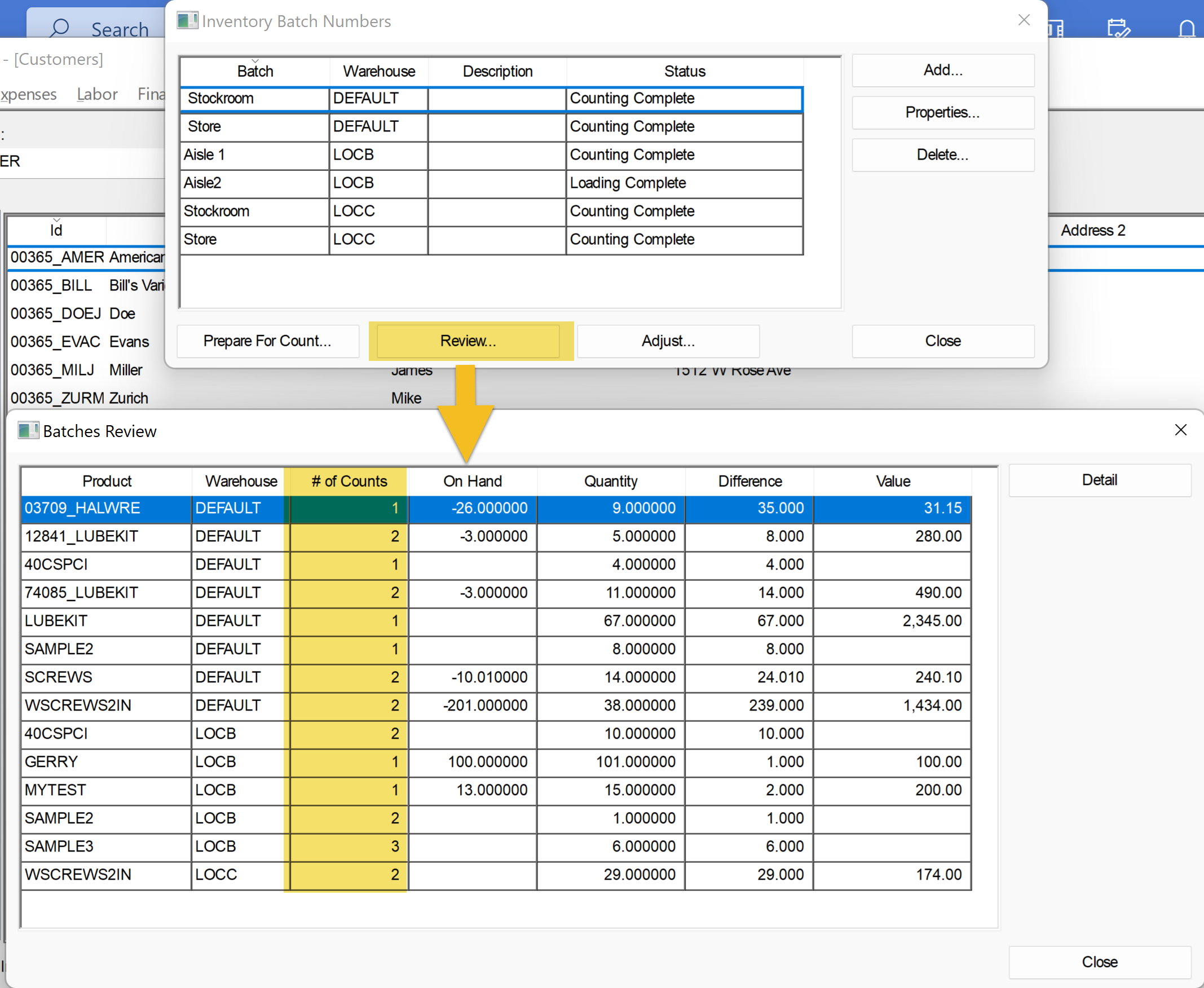

Go to on the main EBMS menu to open the Inventory Batch Numbers dialog shown below:

-

Click Prepare For Count just prior to taking the physical inventory count. This captures the current quantity of inventory on hand and will be compared against the physical inventory quantity to determine the adjustment. This feature enables the inventory manager to review and verify that the physical count is accurate even while inventory is being purchased and sold. The following dialog will appear only if inventory is managed within multiple warehouses:

NOTE: Prepare Count needs to be run and Inventory Counts entered before buying and selling may resume.

-

Select the Warehouses you wish to prep for counts.

2. Creating Batches

The product inventory may be divided into multiple batches based on location, categories, or other grouping. Do not create duplicate batch product lists for the same area. Do not create separate batches for each staff member if a team is counting

the same area. The non-blank product line within each batch will be added together to create a sum of the product inventory on-hand.

Complete the following steps to add batches:

- Click on the Add button to open the Add Batch dialog as shown above:

-

Enter a Batch ID and Description to identify a batch. Include the location, product, and date of the batch.

-

Select a Warehouse if multiple warehouses are present and click OK. A batch can contain information for only one location or warehouse. Multiple batches must be created if inventory is counted

from multiple locations.

-

The Status column gives the following snapshot of where each batch is at in the count cycle process. Periodically through the count cycle process the Status needs to be updated before

proceeding to the next step.

-

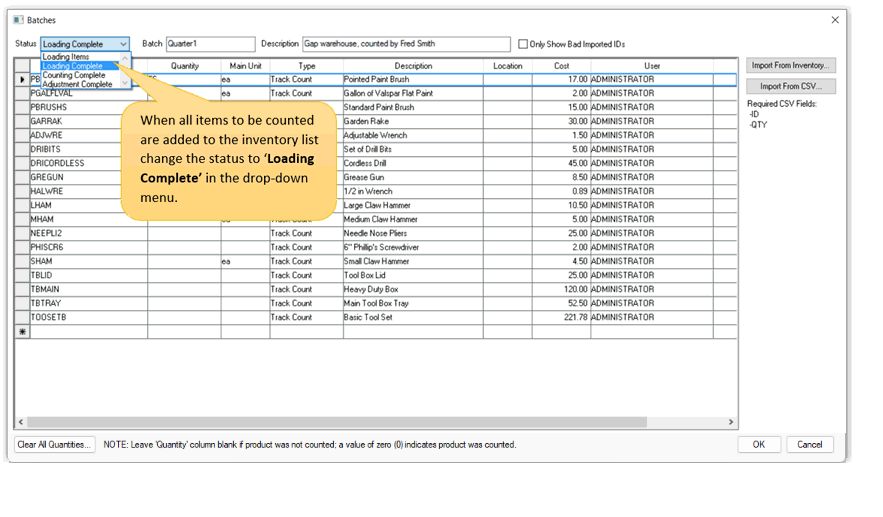

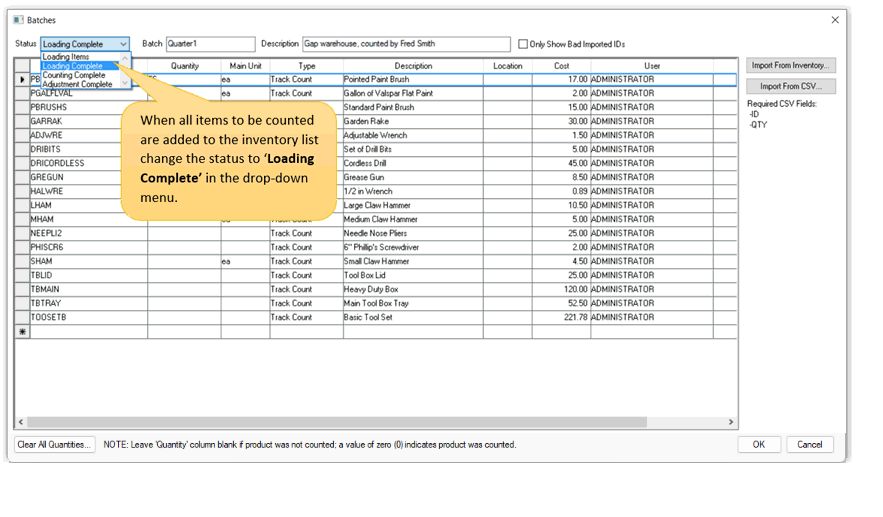

Loading items: Items are still being added to the list

-

Loading Complete: The inventory items for a batch are loaded. counting, verifying, and entering counts into EBMS are currently in process.

-

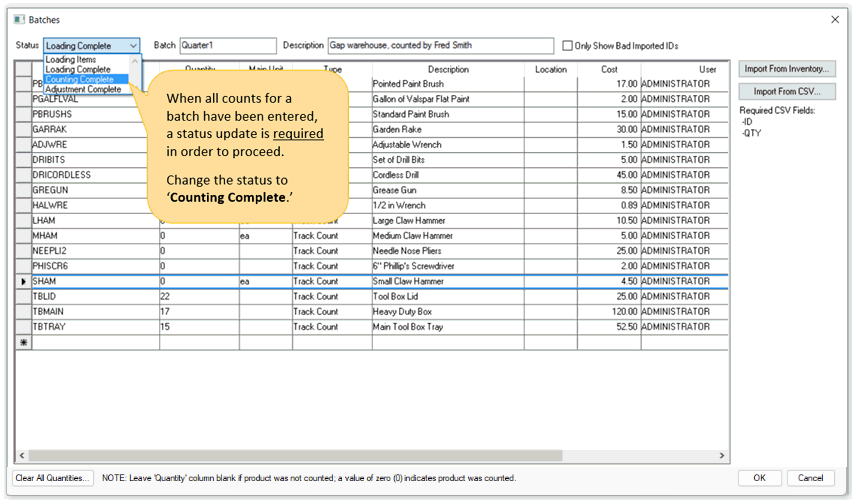

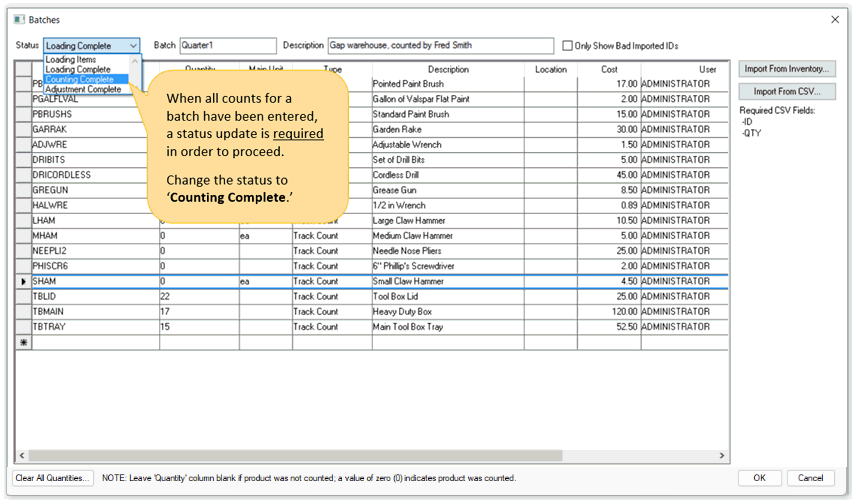

Counting Complete: The inventory list has been counted. Counts have been entered and inventory is ready to be adjusted.

-

Adjustment Complete: When batches are processed, the status changes to 'Adjustment Complete.' No additional changes may be made to the batch.

-

Click Properties to configure a list of inventory Items that need to be counted or adjusted.

-

The user can add items to this list using the following methods:

-

Import from the product catalog: Click on the Import from Inventory button as shown below:

-

Import from a CSV file: ID ('Product' column) and QTY ('Quantity' column) fields are required within the CSV file. Clock on the Import from CSV

button as shown below:

The following dialogs will appear after the file has been selected:

-

Barcode Scanner: Inventory items can be added to this list using a barcode scanner programmed as keyboard wedge. All products will be populated with the main unit of measure.

-

Manually enter product items and count contained within the batch location:

-

Only perpetual inventory items classified as Track Count, Serialized Items, or Lot will be added to the batch. Review Product Catalog > Item Classifications for a list of perpetual inventory classifications..

-

Manually change the Status from Loading Items to Loading Complete as shown below:

Note: Batch counts are added together to create a total count of product in stock. Duplicate items with count values will increment the total on-hand value.

3. Counting Items

Once the status of the inventory list is changed to 'Loading Complete' the counts for each item may be entered. Complete the following steps to enter counts:

-

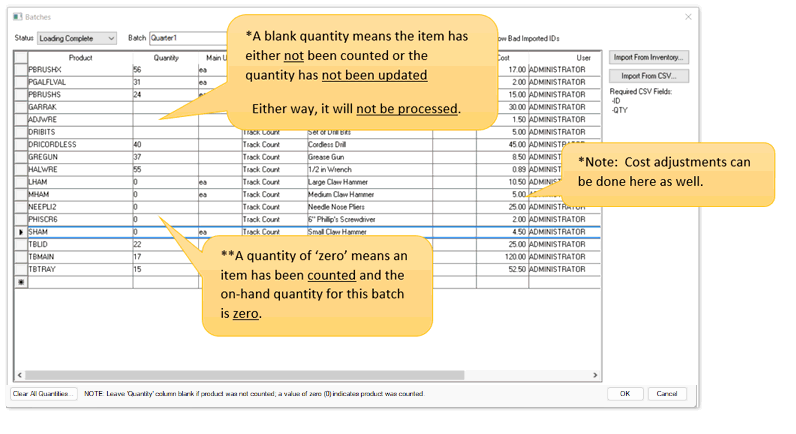

Within the Batches entry dialog, enter or adjust the quantity of each item you wish to change to reflect the new updated count of the batch. Use one of the following methods to adjust counts:

-

Enter counts manually:

-

Import counts from a CSV file with the Import from CSV button demonstrated previously: Products listed on multiple spreadsheets will be added together to create a total during the review process.

The cost value is defaulted from the Product Cost field and is used during the adjustment when increased quantity. Decreases in the quantity will

reduce the inventory value by the FIFO cost.

-

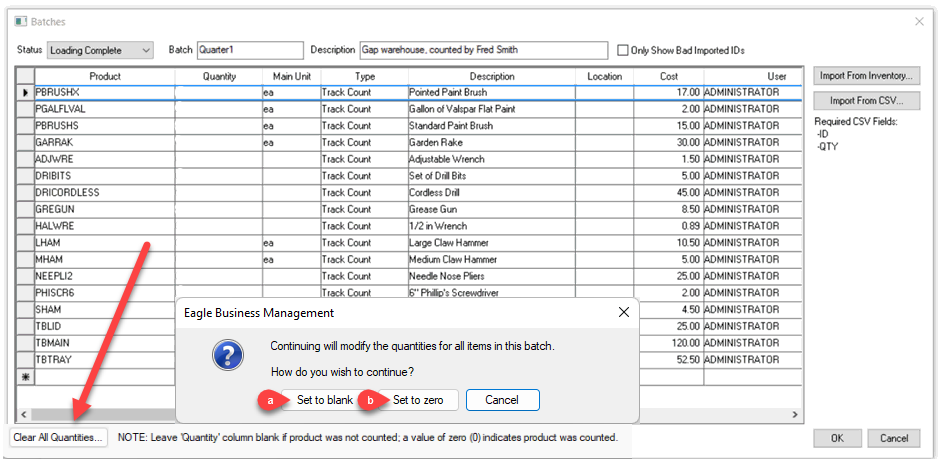

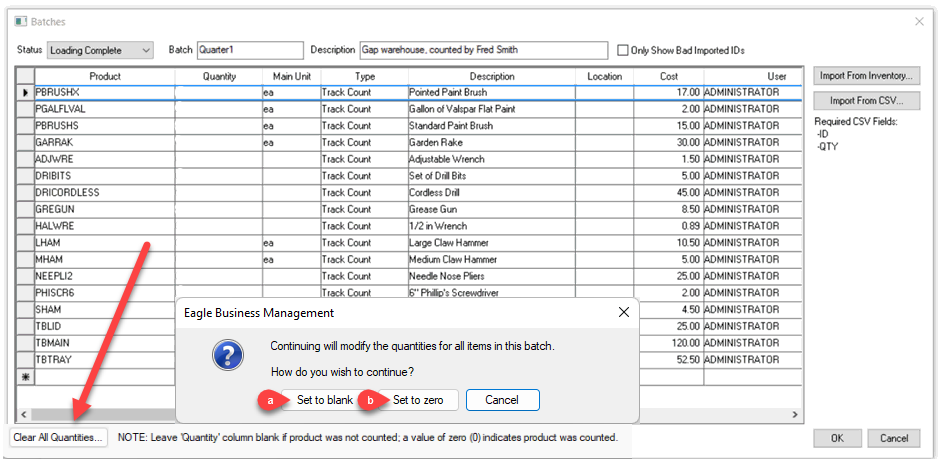

Click Clear All Quantities button to set the quantities of all items based on the following option dialog:

-

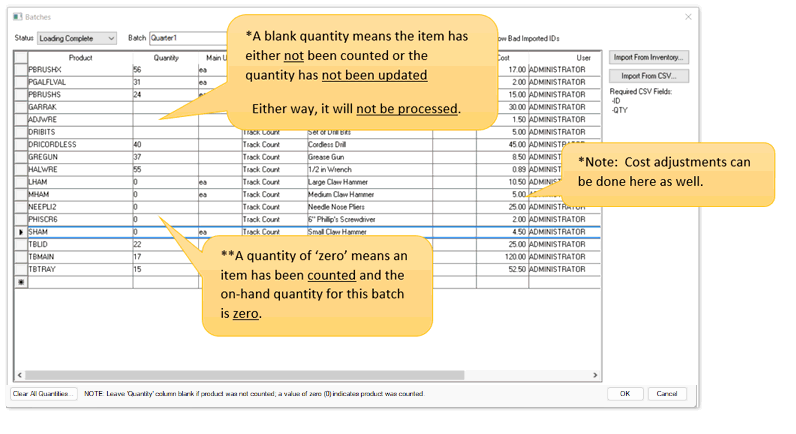

Set to blank: A blank value will cause the system to ignore any changes to the associated product. This option can be used to only adjust products that contain a value of zero or non-zero. All blank lines are ignored.

-

Set to zero: A zero value adjusts the count to zero rather than ignoring the count.

For example, A Garden Rake Quantity of zero will adjust any inventory count to zero and a clear value (blank) will not adjust the Garden Rack on-hand inventory quantity.

Note: A batch with products that were not counted must have a blank Quantity rather than a quantity of zero. Zero should only be used when no inventory exists.

4. Count Complete

Change the Status setting to Counting Complete as shown below:

5. Review Counts

All Inventory batches must have a status of 'Counting Complete' in order to process adjustments.

Click Review to review counts as shown below:

The # of Counts column indicates the number of lines within the imported batches. This value can be very useful to verify that all valid counts are included. Note that batch lines with a blank Quantity rather than

a value of zero would not be included in this total.

The Quantity value is the sum quantity of every batch.

Review the totals and adjustments of each item. Click on an item and click the Details button to view the individual count entries for the selected items.

6. Adjust Counts for All Batches

Counts are adjusted for and item using all batches.

WARNING: Do not use duplicate batches with values for the same product in multiple batches. Total sum total of each product within all batches is used to calculate the adjustment.

Complete the following steps to adjust counts in EBMS.

- Click on the Adjustments button to open the Adjust Inventory dialog:

-

Set the Adjustment Date that will be used for all adjustment financial transactions. Use the end of last fiscal year if this count adjustment is an end-of-year inventory count.

-

Set the Adjust on Hand to Quantity Counted option to adjust the On Hand value based on the adjustment shown in the previous review step. The new On Hand quantity may differ from the review On Hand value (in previous review

step) if the On Hand count has changed since any of the batches were created.

-

Click the Adjust button to launch the count adjustment process for all the batches.

- Click Yes to launch the adjustment process.

-

The following information window will appear when the 'Adjust Inventory Count' was successful.

7. Reporting Adjustments

Open a product and click on the Activity tab to view adjustments for a single item. Review Product Catalog > Sales and Purchase Activity for more information on the Activity tab.

-

Generate the report to list all adjustments between two dates.