Purchasing Special Orders

Special order items and items identified as Drop Ship within

the sales order must be "purchased" before the sales order can

be processed. The purchasing step is accomplished by linking the sales

order to the purchase order. This step can be done using any of the following

steps:

Linking the purchase directly from the sales order

detail line - This option is useful when a single line item is purchased

immediately from the vendor.

Purchasing the entire sales order - This purchase

option is used extensively for drop ship orders or when most of the

sales order lines are purchased immediately from the vendor.

Purchasing special order items from the Special

Orders tab of the purchasing screen - This popular option allows

the user to purchase special order items after the sales order is

created an saved. This option should be used when the purchasing

staff places the orders for products sold by a separate sales team. Using

the Purchasing window facilitates the ordering of special order items

and stocked items from a common interface.

Creating a purchase order from MyTime. Review

[Labor]

MyTime > Adding Products to a Task or Work Order for more details

on this method of special order purchasing.

Note that purchase order lines can be created from a sales order without

using an inventory item. The quantity, Description,

and Vendor Part Number are copied

to the purchase order with either of the 4 purchasing options.

Linking special orders and drop shipments to a purchase order should

be done at the time the items are ordered from the vendor. Review the

instructions below for each of the three linking options:

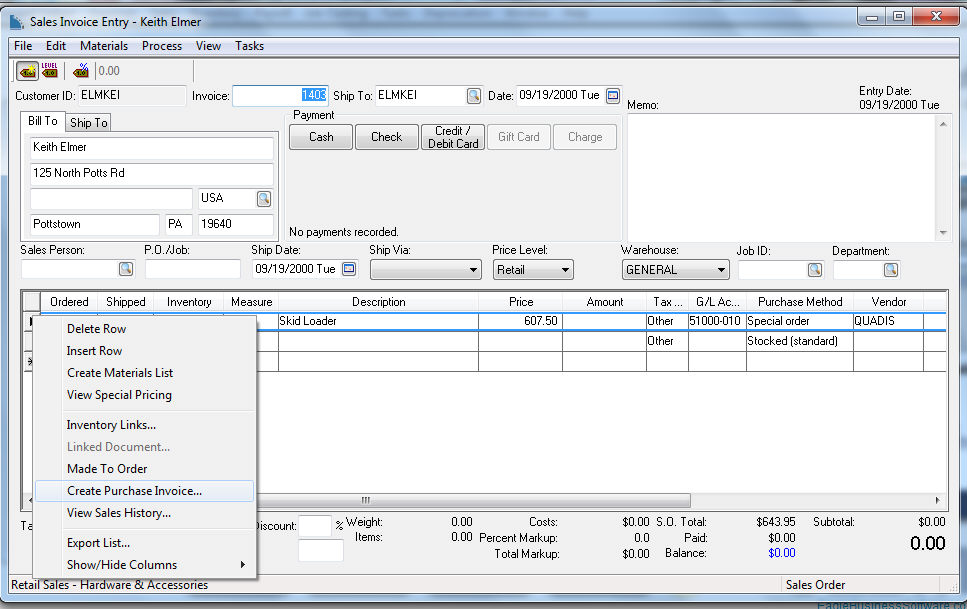

A. Linking the purchase directly from the sales order detail

line

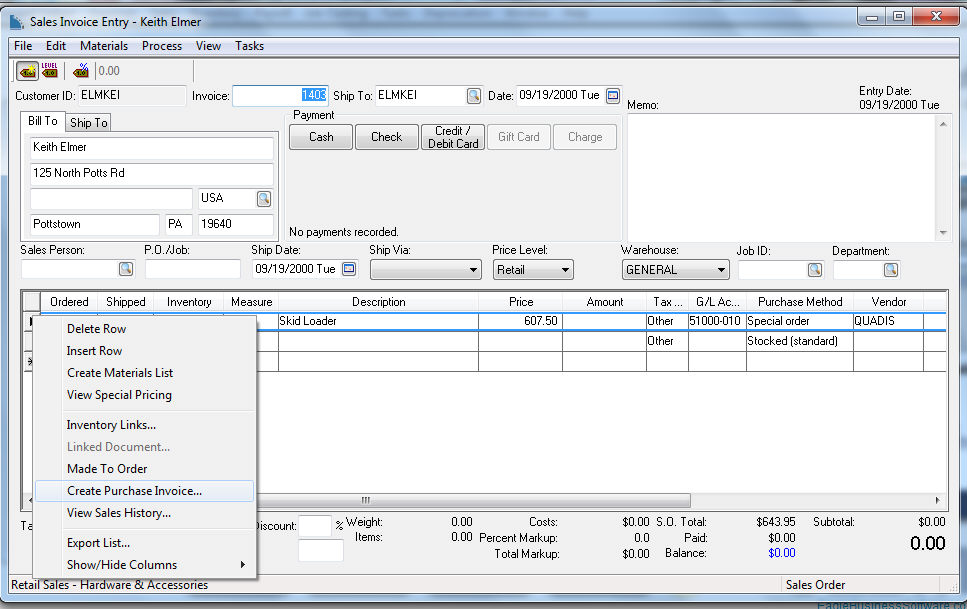

Right click on the detail line to link a purchase order directly

to a specific line item of a sales order as shown below:

The Create Purchase Invoice

option will only appear if the Purchase

method is set to Special Order, Drop Shop, or Replenishment

and if a Vendor code is entered.

The option will also not be available if the line item has already

been linked to a purchase order. The following dialog will not appear

if the Purchase method is

set as Drop Ship.

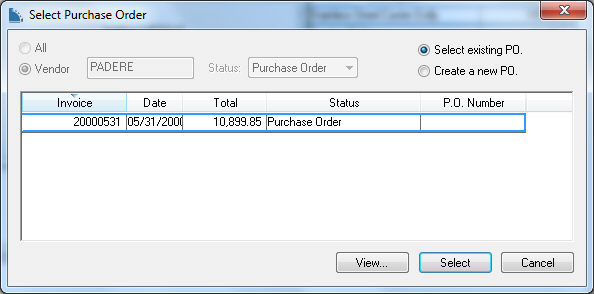

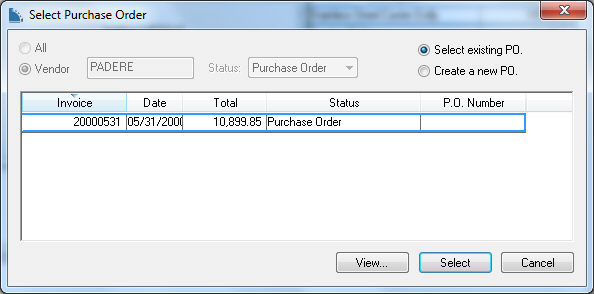

Select the Create a new PO

option if you do not wish to append to an existing purchase order.

Click on the Select existing

PO and configure the All/

Vendor settings to select

an existing purchase order.

Click on the Select

/ Create button to create

the purchase order as shown below:

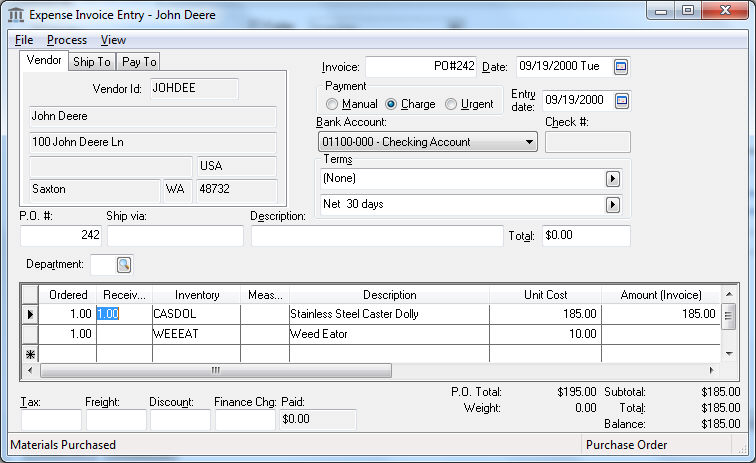

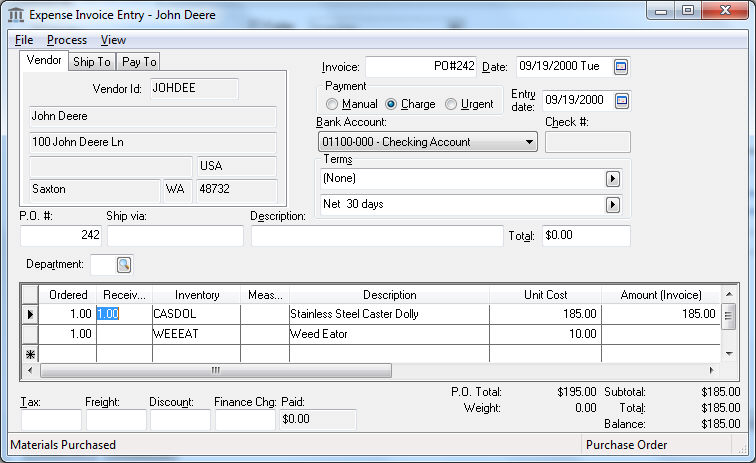

The Ordered quantity,

Description, and Vendor Part

Number is copied from the sales order to the Received,

Description, and Vendor Part

Number columns of the purchase order.

The Received quantity of the

purchase order is linked to the Shipped

quantity of the sales order if the Purchase

Method is set as Drop Ship

or Sync Quantities. These

special order transactions will not affect the inventory On-hand

count of the inventory item since these values always match. Use the

Associated method if the quantity

fields should not be synchronized. Populate the Received

quantity when special order items are received from the vendor.

Drop shipments will never be handled by the user since the product is

shipped directly from the vendor to the customer. Populate and process

both invoices at the time the product has been shipped to the customer

and the sales order is processed. The Shipping

Customer ID within the Ship To

tab of the purchase order will be populated with the Customer

ID within the sales order for drop ship purchase orders. Right

click on any of the drop ship detail lines of the purchase order and select

Linked Document from the context

menu to view the associated drop ship sales order.

B. Purchasing the entire sales order

This purchasing option is the recommended method used for sales orders

that contained dropped shipped items especially if the sales order includes

multiple items that are shipped on the same purchase order.

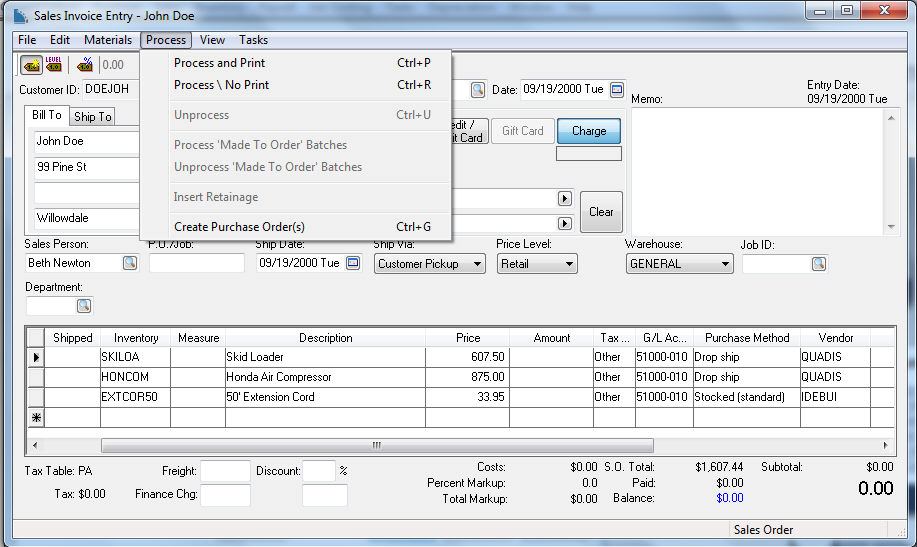

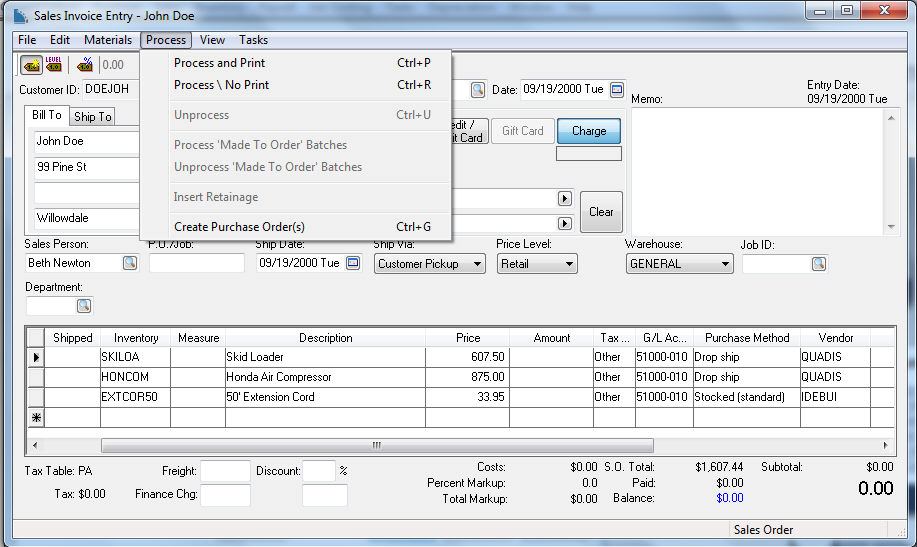

Open the sales order and select Process

> Create Purchase Orders(s) from the sales order menu as

shown below:

Review the previous section for details on the wizard to create the

purchase order.

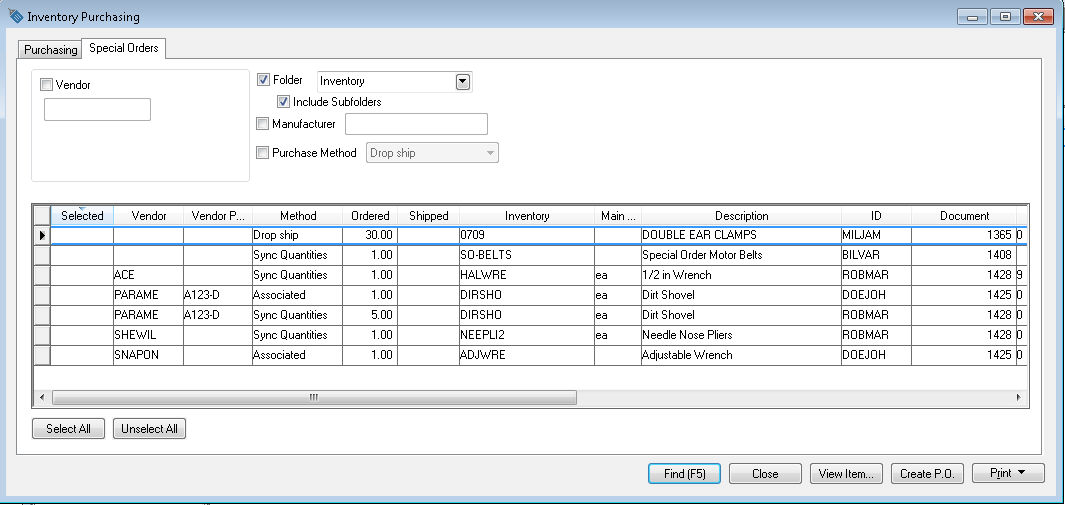

C. Purchasing special order items from the Special Orders tab of the

purchasing screen

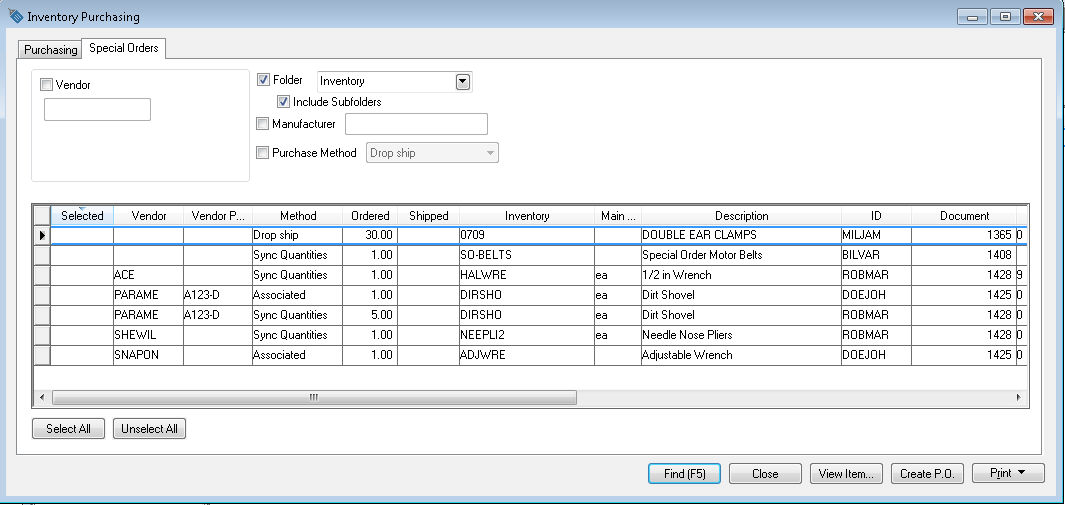

The Purchasing Window contains

a Special Orders tab that lists

all the special orders and drop shipments that are not linked to a purchase

order.

Go to Inventory > Purchasing

and click on the Special Orders

tab as shown below:

Click on the Find (F5)

button or hit the F5 keyboard

key to list all the special order items the match the query option

on the top of the window. All special order items will be listed if

all the query options are disabled as shown above. Set any of the

following query options to limit the special order list:

Enable the Vendor

option to list only the special orders that are set to be purchased

from the selected Vendor.

Enable the Folder

and the Include Subfolders

options to limit the list to special order items from a specific

folder group or subfolders. Review the Product

Catalog > Adding and Deleting Inventory Folders section

for more details on inventory item folders.

Enable the Manufacturer

option to list only items associated by a single manufacturer.

The Manufacturer setting

is found within the General

tab of the inventory item.

Enable the Purchase

Method option and select a specific method to limit the

special order lists to one of the Purchase

Method settings - Drop

ship, Replenishment, Sync Quantities and Associated.

Review the Purchasing > Purchasing

Methods section for more details on these options.

Note that the Find (F5)

button must be clicked to refresh the list of items.

Enable the Selected

option (first column of item list) for each item you wish to place

on the purchase order. Click on the Create

P.O. button to link Selected

special orders to a purchase order.

The special order list can be evaluated when the Create

PO is launched from the main Inventory

Purchasing window by enabling the View

when creating purchase order option within the Inventory

> Options > General tab. Review the Purchasing

> Using the Purchasing Window to Create Purchase Orders for details

on this option.